RESEARCH & TESTING

Product development drives Soben International evolving towards in response to the market changes and needs. The growth of the company not only base on quality product range, but also advising a broad of range of clients on practical solutions for various building applications that meet the code of practice, design and building regulations. We collaborate with research institute of the university for new material technology applied that strengthens our production and continuously refine products. Soben International Technical Department so far have been conducting a considerable number of testing on materials, products and system applications particular in fire resisting construction. A great deal of fire tests has been carried out in accredited laboratories worldwide and notified laboratories in Europe. Necessity of technical appraisals are prepared by world class fire consultants ensuring adequate functionalities of the specialised fire protection solutions are fit-to-purpose. The strong proven fire resistance performance of Soben International product range and fire solutions provide authentic protection of life, properties and the environment. After all it delivers peace of mind in fire-safe and confidence for clients and end users.

Soben International fire-safe Systems & Solutions have been developed and tested with respective to the latest international fire codes for buildings and industrial aspects.

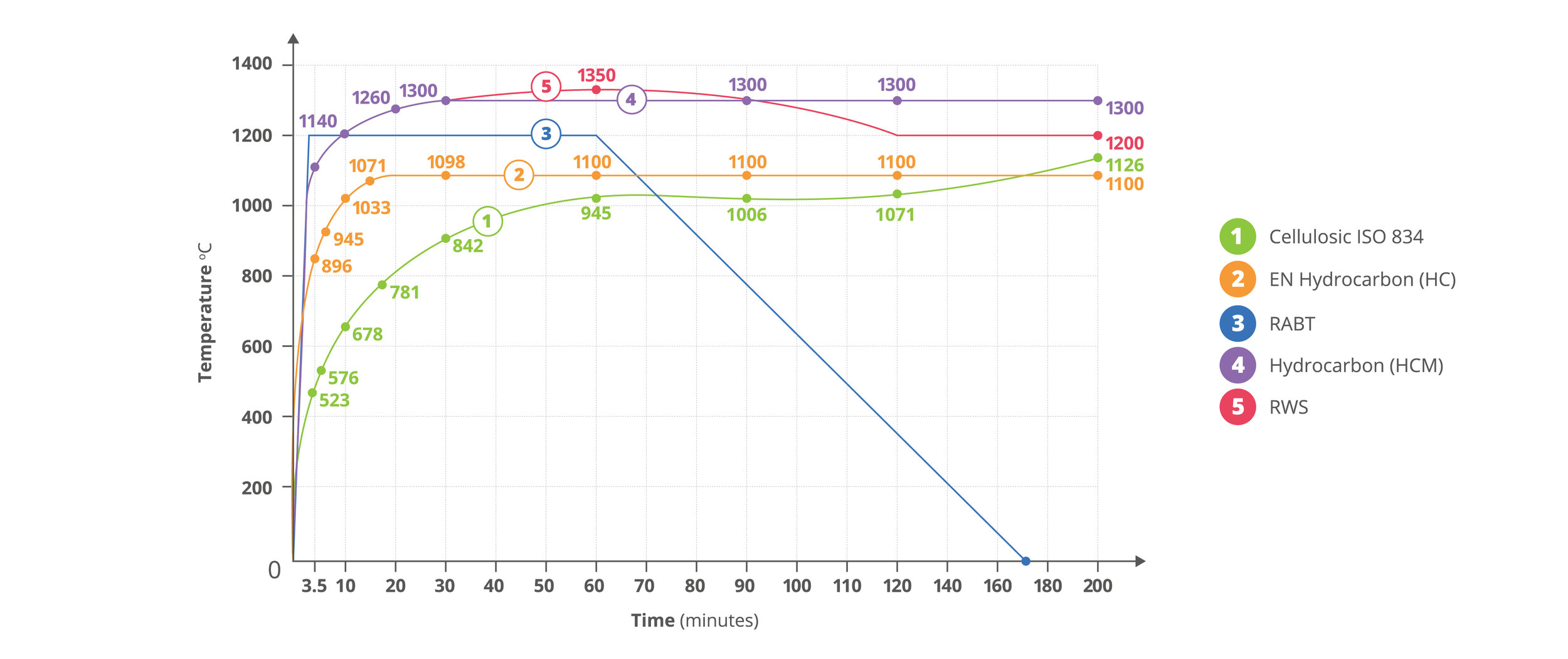

Fire Load Curves

Fire development in a structure is classified as two types of fire, either cellulosic or hydrocarbon fire. The difference between two types of fire is the time it takes for the fire to reach its maximum temperature range. The burning rate of cellulosic fires is comparably slow due to general combustible building materials and building contents. On the contrary, hydrocarbon fires develop extremely fast because of high burning rate of hydrocarbon chemicals in petrochemical facilities or fuels from cars in tunnels. Under test conditions, a cellulosic fire will reach a temperature of 945°C in 60 minutes, whilst a hydrocarbon fire will take just a few minutes to reach the same level.

Cellulosic fire

Standard fire tests for building elements are based on the use of cellulosic fire, a standard temperature-time curve ISO 834 as a common benchmark and defined in various national standards, e.g. BS 476: Part 20, EN 1363-1, AS 1530, DIN 4102, etc.

The ISO 834 fire load curve in the graph represents a fully developed fire in a compartment and shows that temperature increases with time at a constant rate, as defined by the following expression:

T=20 + 345log10 (8t+1)

Hydrocarbon fire

Hydrocarbon chemicals and fuels ignite with high intensive of fire and thermal radiation. Within ten minutes of ignition, the temperature of the hydrocarbon fire can reach 1000°C when a fire occurs in a confined space of tunnel. Unprotected reinforced concrete linings of the tunnel may collapse due to loss of strength and spalled concretes as their temperature increases. A few researches on hydrocarbon fire nature in tunnel had been taken place recent years. These are Hydrocarbon Eurocode 1 (HC), Modified Hydrocarbon (HCM), Rijkwaterstaat (RWS) and RABT fire curves with attributes of time-temperature change. The HC and RWS standards are increasingly adopted in many tunnel constructions.

More details of Soben International passive fire protection solutions for buildings and tunnels, please visit our Project Gallery here.

Fire Time-temperature Curve